Electrical switches are important ‘electrical devices’ for switching electrical circuits on and off.

Today, they are used in homes, workplaces, schools and many other places.

The manufacturing of electrical switches requires a very meticulous process. In this article, we will provide detailed information about the manufacturing of electrical switches.

The manufacturing process of electrical switches usually consists of four stages:

Material Preparation

The materials used in the manufacture of electrical switches are various materials such as plastic, yellow brass, copper, silver contacts, screws and nuts.

Plastics are shaped in injection molding machines. This process is done for the purpose of housing the body, cover and internal parts of the switch and insulating the electricity.

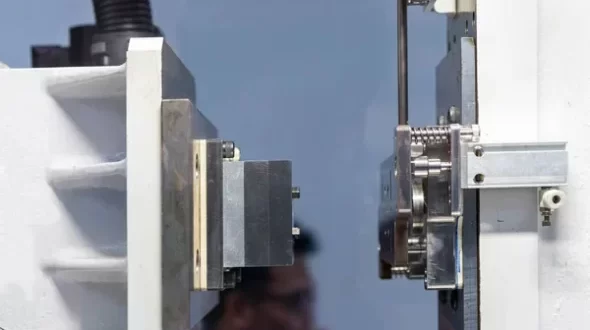

Yellow brass or copper metals are cut into strips in eccentric presses and shaped to fit the housing. Silver contacts are mounted on yellow brass or copper materials to ensure smooth conductivity.

Welding the silver maximizes the conductivity of the switches and prevents heating, deformations and provides better results to extend the life of the switches. Fasteners such as screws and nuts are used for wiring the switches.

Part Manufacturing

Part manufacturing can vary according to the type and complexity of the switch. Simple keys can be manufactured with a few parts, while more complex keys may consist of more parts. The manufactured parts are then assembled in different ways and joined together to form a key.

Assembly

The parts are assembled into the interior of the switch after automation and/or manual assembly. The interior may contain conductive metals, silver contacts, neon lamps, springs and other components to ensure the electrical characteristics of the switch. The outer protection or cover parts are assembled and finalized.

Testing and Quality Control

At the end of the production process, electrical switches are 100% checked and final quality control is performed. This is done to ensure that the product is robust and safe.

For example, during the tests, the switch is tested for its construction and mechanical working condition, conductivity, heat resistance, dielectric strength. Electrical tests are also carried out to prevent any safety hazards.